Kaizen is a powerful thinking. It refers to business activities that continuously improve all functions by integrated approach. The methodology applies to processes that cross organizational boundaries into the supply chain.

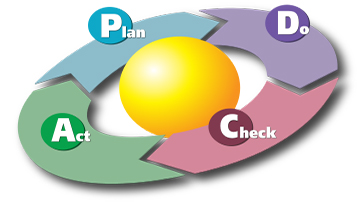

Cycle of Kaizen

A management system is a set of policies, processes and procedures used by the organization to ensure that it can fulfill the tasks required to achieve its objectives. We think that the management system should be subject to continuous improvement as the organization learns. The business concept of Kaizen is therefore a very good tool. A simplification of the main aspects is the 4-element cycle of the Kaizen approach. This cycle of activity can be defined as: Plan → Do → Check → Act. With an important underlying goal. That by improving standardized programmes and processes, the concept aims to eliminate waste.

Truly effective

The company as a whole had to embrace it and allowed it to become a company philosophy for it to truly work as originally intended. Top to bottom accepted that the improvements are being made for the betterment of the company as a whole. Employee empowerment is huge and every effort is made to promote the concept that everyone has a stake in the results. It is a daily process. The concept is also a process that, when done correctly, humanizes the workplace, eliminates overly hard work, and teaches people how to perform experiments on their work and how to learn to spot and elimimate waste in business processes.

Kaizen on a broad, cross-departemental scale in the company, generates our quality management. Please do not hesitate to contact us with any inquiries regarding this subject or if you need any information about support possibilities.